Horizontal Form Fill Seal (HFFS) technology has revolutionized the packaging industry with its ability to create a wide range of package styles efficiently and cost-effectively. From food and pharmaceuticals to consumer goods and industrial products, HFFS offers a versatile solution for packaging diverse products with enhanced protection, extended shelf life, and improved brand appeal.

This blog post delves into the intricacies of Horizontal Form Fill Seal technology, exploring its working principles, key benefits, and diverse applications across various industries.

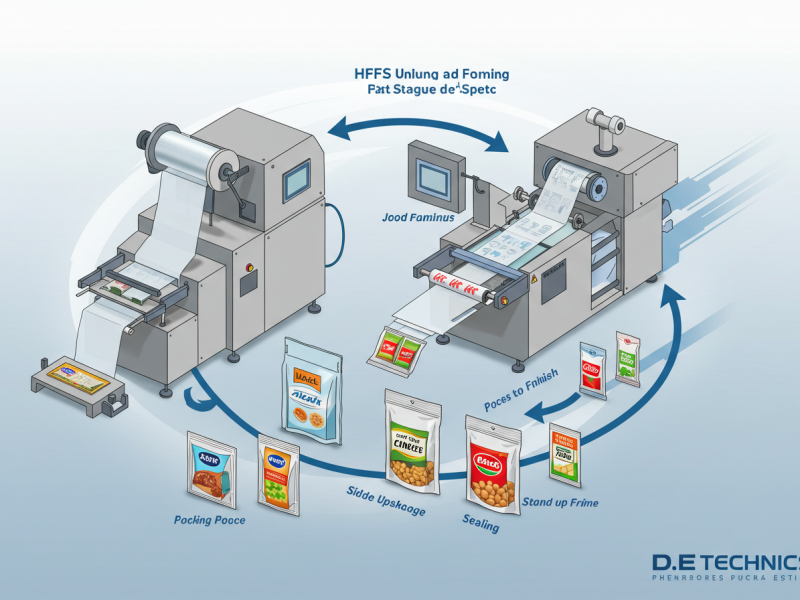

Understanding the HFFS Process

HFFS machines operate on a continuous cycle, transforming a roll of flexible packaging material into finished packages. The process involves several key steps:

- Film Unwinding and Forming: A roll of flexible packaging material is unwound and fed into the machine. The film is then shaped into a tube by forming shoulders or a forming collar.

- Longitudinal Sealing: The longitudinal seam of the tube is sealed, creating a continuous pouch.

- Filling: The product is accurately measured and dispensed into the formed pouch.

- Cross Sealing and Cutting: The filled pouch is sealed at regular intervals, creating individual packages. The packages are then cut and separated.

A modern predictive maintenance system using AI to monitor equipment health

These implementations are already delivering significant benefits. According to a recent industry survey, manufacturers using AI-powered predictive maintenance have seen a 20% reduction in downtime and a 25% decrease in maintenance costs. Similarly, AI-based quality control systems have reduced defect rates by up to 90% in some applications.

Key Benefits of HFFS Technology

HFFS technology offers numerous advantages for packaging various products:

- Versatility : HFFS machines can create a wide range of package styles, including pillow pouches, gusseted pouches, stand-up pouches, sachets, and more, catering to diverse product needs and branding requirements.

- Efficiency: Automated operation and high-speed capabilities increase productivity and reduce labor costs, making HFFS a cost-effective packaging solution.

- Product Protection: Secure seals and various packaging material options protect products from moisture, oxygen, light, and contamination, extending shelf life and preserving quality.

- Brand Appeal: HFFS packaging allows for attractive designs, clear windows, and convenient features like resealable zippers, enhancing product presentation and attracting consumers.

- Material Flexibility: HFFS machines can accommodate a wide range of flexible packaging materials, including laminates, films, and co-extruded materials, allowing for customization based on product needs and sustainability goals.

Applications of HFFS Across Industries

HFFS technology finds applications in a wide range of industries:

- Food Industry: HFFS is used to package snacks, confectionery, bakery products, frozen foods, coffee, tea, spices, and more, preserving freshness and extending shelf life.

- Pharmaceutical Industry: HFFS is used to package medical devices, pharmaceuticals, nutraceuticals, and vitamins, ensuring product sterility and protection.

- Consumer Goods Industry: HFFS is used to package hardware, electronics, personal care products, cleaning supplies, and more, offering convenience and attractive presentation.

- Industrial Packaging: HFFS is used to package various industrial products, such as powders, granules, and liquids, offering efficient and cost-effective solutions.

DETechnics HFFS Solutions: Tailored to Your Needs

DETechnics offers a comprehensive range of HFFS machines designed to meet the diverse needs of various industries. Our HFFS machines are built with:

- High-quality materials and components: Ensuring durability, reliability, and long service life.

- Advanced technology: Providing precise control, high speed, and efficient operation.

- User-friendly interfaces: Making operation and maintenance simple and intuitive.

- Customization options: Allowing for tailoring machines to specific product and packaging requirements.

Our team of experts can help you select the ideal HFFS machine for your specific needs and provide ongoing support to ensure optimal performance.

Real-World Examples of HFFS Applications

Case Study 1: Efficient Packaging of Granular Products

A fertilizer manufacturer, [Brand Name], was seeking an efficient and cost-effective solution for packaging their granular fertilizer products. They were using a manual packaging process that was slow, labor-intensive, and prone to spillage.

DETechnics helped them implement an HFFS machine with a specialized auger filling system for accurate and efficient packaging of granular products. The new machine significantly increased production speed, reduced labor costs, and minimized product waste.

Results:

- Production output increased by 40%.

- Labor costs reduced by 25%.

- Product waste minimized through accurate filling.

- Improved packaging consistency and product presentation.

Case Study 2: Versatile Packaging for a Cosmetics Company

A cosmetics company, [Brand Name], wanted to expand their product line with a new range of liquid soaps. They needed a packaging solution that could handle different product viscosities and create attractive, stand-up pouches with convenient dispensing features.

DETechnics provided them with an HFFS machine capable of handling liquid filling and forming stand-up pouches with spouts. The new machine allowed them to efficiently package their liquid soaps in attractive and functional pouches, enhancing their brand appeal and expanding their product offerings.

Results:

- Efficient and versatile packaging for liquid products.

- Enhanced product presentation and brand appeal.

- Expanded product line and increased market reach.

Conclusion

Horizontal Form Fill Seal technology offers a versatile and efficient packaging solution for diverse industries. By leveraging the benefits of HFFS and partnering with DETechnics, you can optimize your packaging process, enhance product protection, and elevate your brand.

Contact us today to discuss your packaging needs and explore how DETechnics' HFFS solutions can benefit your business.